Cross-connection control and backflow prevention

The City of Hayward has a cross-connection control program to protect the city’s drinking water distribution system from contamination caused by backflow.

City of Hayward Cross-Connection Control Program

24505 Soto Road

Hayward, CA 94544-1432

510.881.7966

crossconnection@hayward-ca.gov

Read the Consumer Guide to Backflow Prevention

Standard Details

Click to view Standard Details

Frequently Asked Questions

What is a cross-connection?

A cross-connection is any temporary or permanent connection between a public water system or consumer’s potable (i.e., drinking) water system and any source or system containing nonpotable water or other substances. An example is the piping between a public water system or consumer’s potable water system and an auxiliary water system, cooling system, or irrigation system.

What is backflow?

Backflow is the undesirable reversal of flow of nonpotable water or other substances through a cross-connection and into the piping of a public water system or consumer’s potable water system. There are two types of backflow--backpressure backflow and backsiphonage.

What is backpressure backflow?

Backpressure backflow is backflow caused by a downstream pressure that is greater than the upstream or supply pressure in a public water system or consumer’s potable water system. Backpressure (i.e., downstream pressure that is greater than the potable water supply pressure) can result from an increase in downstream pressure, a reduction in the potable water supply pressure, or a combination of both. Increases in downstream pressure can be created by pumps, temperature increases in boilers, etc. Reductions in potable water supply pressure occur whenever the amount of water being used exceeds the amount of water being supplied, such as during water line flushing, firefighting, or breaks in water mains.

What is backsiphonage?

Backsiphonage is backflow caused by a negative pressure (i.e., a vacuum or partial vacuum) in a public water system or consumer’s potable water system. The effect is similar to drinking water through a straw. Backsiphonage can occur when there is a stoppage of water supply due to nearby firefighting, a break in a water main, etc.

Why do water suppliers need to control cross-connections and protect their public water systems against backflow?

Backflow into a public water system can pollute or contaminate the water in that system (i.e., backflow into a public water system can make the water in that system unusable or unsafe to drink), and each water supplier has a responsibility to provide water that is usable and safe to drink under all foreseeable circumstances. Furthermore, consumers generally have absolute faith that water delivered to them through a public water system is always safe to drink. For these reasons, each water supplier must take reasonable precautions to protect its public water system against backflow.

What is a backflow preventer?

A backflow preventer is a means or mechanism to prevent backflow. The basic means of preventing backflow is an air gap, which either eliminates a cross-connection or provides a barrier to backflow. The basic mechanism for preventing backflow is a mechanical backflow preventer, which provides a physical barrier to backflow. The principal types of mechanical backflow preventer are the reduced-pressure principle assembly, the pressure vacuum breaker assembly, and the double check valve assembly.

What is an air gap?

An air gap is a vertical, physical separation between the end of a water supply outlet and the flood-level rim of a receiving vessel. This separation must be at least twice the diameter of the water supply outlet and never less than one inch. An air gap is considered the maximum protection available against backpressure backflow or backsiphonage but is not always practical and can easily be bypassed.

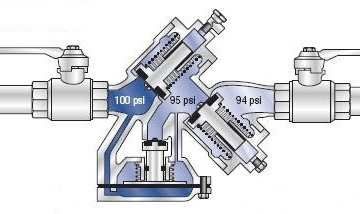

What is a reduced-pressure principle assembly (RP)?

An RP is a mechanical backflow preventer that consists of two independently acting, spring-loaded check valves with a hydraulically operating, mechanically independent, spring-loaded pressure differential relief valve between the check valves and below the first check valve. It includes shutoff valves at each end of the assembly and is equipped with test cocks. An RP is effective against backpressure backflow and backsiphonage and may be used to isolate health or nonhealth hazards.

What is a double check valve assembly (DC)?

A DC is a mechanical backflow preventer that consists of two independently acting, spring-loaded check valves. It includes shutoff valves at each end of the assembly and is equipped with test cocks. A DC is effective against backpressure backflow and backsiphonage but should be used to isolate only nonhealth hazards.

Why do backflow preventers have to be tested periodically?

Mechanical backflow preventers have internal seals, springs, and moving parts that are subject to fouling, wear, or fatigue. Also, mechanical backflow preventers and air gaps can be bypassed. Therefore, all backflow preventers have to be tested periodically to ensure that they are functioning properly. A visual check of air gaps is sufficient, but mechanical backflow preventers have to be tested with properly calibrated gauge equipment.

How does Hayward protect against backflow?

The City requires the installation of backflow prevention assemblies whenever a potential hazard is present within a consumer’s premises. Assemblies can be required near the water meter (as close as practical) to protect the public water supply.

As an owner of a backflow prevention assembly, what are my responsibilities?

The City schedules your backflow prevention assembly test, conducts the test and will notify you if the device fails and needs repair. As the customer, you have the responsibility to get the device repaired and contact the City to get it re-tested.

If you to move, remove or replace a backflow prevention assembly, you must first get the approval of the City’s Cross-Connection Control Specialist. The Specialist will need to know the new location and why you want to move the device, or if it is a replacement, the Specialist will require that the replacement device meet the requirements for meter protection and be included on the List of Approved Backflow Prevention Assemblies.

Whenever you move, repair, or install a device, it must be tested immediately and the test results submitted.